Humans love consistency. Sure, we occasionally want to be scared, or surprised, or to discover new things. But we mostly like things to be predictable.

It’s nice to know that a Hershey bar is always going to have the same predictable taste. It’s nice to know that a Big Mac in Los Angeles tastes the same as the one in Orlando. It’s nice to know that the Starbucks at the Hobby Airport in Houston will give you the same delicious coffee as a Starbucks in Seattle.

We value consistency so much that we have developed vocabulary to describe it in the different areas of life. Investments that have high variation in the rate of return are called high risk, while investments that deliver a consistent rate of return are low risk. People who behave inconsistently are considered unreliable. And when we’re talking about consistency in a product or service, we often refer to it as quality. Managing that quality over time is called quality control.

If consistency is so desirable, how do we get it at work? How do we consistently deliver the same high-quality product or service to our customers, both internal and external?

This is a two-part answer: Process and Automation. In this first blog of the two-part series, we will focus on how to create efficient and effective processes. In part two, we’ll examine automation and its role in increasing quality.

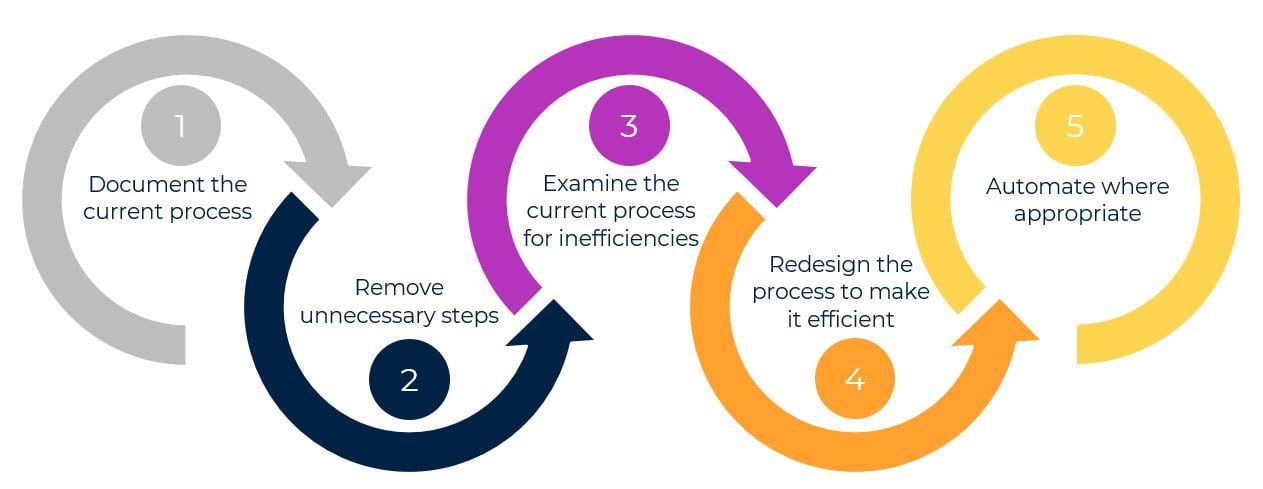

It’s been said that doing the same thing over and over while expecting different results is a type of insanity. Therefore, to get consistent results we must follow a consistent process. We should also make sure we’re only doing the stuff that adds value. And of course, we want to ensure that we’re working efficiently. Since a picture is worth 1,000 words, I’ve included one here.

Step 1: Document the current process

Odds are that most of your company’s processes are not documented. People typically go through an initial training when they start their job and then they just do the job. If you already know what you’re doing, why write it down?

The problem comes later when the person doing the job wants to take a vacation, or the job grows from a one-person job to a two-person job. Without a clearly documented process, two different people will probably do the same job differently. Maybe just a little differently, maybe a lot. Either way, inconsistency rears its ugly head!

That’s why step 1 is to simply document what you do. Write it down. Take some screenshots where appropriate. Include a flowchart, et voila! You have documentation.

I think one reason people don’t document processes is that they are unsure of how to document them. Creating good documentation is both an art and a science. It can be intimidating to get started if you feel like you don’t know what you’re doing. But I promise you this: any documentation is better than no documentation. If you’re documenting your own job, start by writing down what you do and why you do each step.

A documented process has value. You can see the process, examine it, scrutinize it. Let’s do that in the next step.

Expert tip: When two people perform the same job differently, you have a process problem, not a people problem. More training is not the answer. Focus on consistent processes instead.

Step 2: Remove unnecessary steps

Ruthlessly examine the process. Every step in the process must have a reason for performing it, some sort of value associated with it. If it’s not adding value, it’s waste. Remove all waste from the process.

Here’s an example. Let’s say that part of a process is to print out a copy of a document and file it. That step used to be critically important. Now things are different, and that document is being saved electronically into a document management system. There’s no need to print and file now. But it continues to happen because, well, that’s how it’s always been done.

Expert tip: Processes need to be re-examined periodically to make sure they are still relevant.

Step 3: Examine the process for inefficiencies

With the unnecessary steps removed, everything that remains has value. You should know exactly what that value is, too. Now ask yourself, “How can I get the same value more efficiently?”

For example, setting up reference data in an CTRM system is an activity that has value. Imagine an existing process where requests are emailed to the person who enters the reference data. Requests are freeform and often have missing information. The person receiving the requests must ask clarifying questions to ensure the correct data is entered into the system.

Is there some way to make this more efficient?

Expert tip: Making processes efficient has an extra side benefit. Besides saving money, you also get happier employees. People feel good about themselves and their job when they are making a real contribution. Would you rather be busy or add value?

Step 4: Redesign the process to make it efficient

The above process is inefficient for two reasons.

- The requests are sent as freeform emails. Using a form or template will ensure that the requester is prompted for all required data.

- The freeform request does not enforce a standard language for communication. Words can be used that are thought to be interchangeable but really have different meanings. Abbreviations may be used that are familiar to only one of the two parties involved.

It’s tempting to think about IT solutions to these problems, but let’s keep this low-tech: a well-designed document template in Word (or even a paper form) is better than the current process. I’m not advocating a paper form, but do you see how a paper form solves both problems?

Expert tip: Following a process creates quality through consistency. Improving the process produces the same result at a lower cost.

Step 5: Automate where appropriate

Automation is not always required but should always be considered.

Automation means getting a computer or machine to do some portion of a process. Most of the time, organizations automate routine processes to reduce human error and ensure quality results. It also allows people to focus efforts on more strategic work which translates to better quality service. Achieving this requires investing time and money. Like any investment, you must consider whether it makes good financial sense. We will explore this in our next blog about automation.

Expert tip: Regardless of whether you automate, doing steps 1-4 are crucial. It’s a bad idea to automate an inefficient process. Only an efficient, well-documented, airtight process is ready for automation.

In Summary

Creating consistent, streamlined processes is one of the simplest ways to increase profits, especially if you are thinking about automating these processes in the future. It all starts with documenting and consistent refinement before you are ready to automate. Think about your current processes – do you have documented processes in place, do your processes exist but need refinement or are you ready to turn mundane tasks into automated processes? Wherever you are in your journey, we can help get you to the next step.

At Veritas Total Solutions, we can help you compile a complete process inventory per department, document those processes, and select the best ones for automation. We have expertise in both Strategy and Transformation and Technology Solutions, making us uniquely qualified for process improvement and process automation in any industry. Contact us to get started.