A booming business is a good problem to have. As your business scales up, the additional work can affect your company’s departments disproportionately. Some departments will be stretched thin. Should you hire more people?

Adding more people is an easy solution, but in the long run, you’re probably better off scaling smartly using the following alternatives.

First, document and improve your processes

Process improvement is the first, most fundamental alternative to adding labor. In a previous post Scaling Smartly: Create Good Processes Before You Automate, I talked about how following consistent processes create higher quality results – and how automating these processes can lead to even higher results. Having a documented and consistent process is just the first step.

A process can be consistently followed yet still be inefficient. Process improvement requires examining and optimizing a process to reduce waste and to make the process as efficient as appropriate.

The benefits of process improvement are reduced time, effort, and materials. Quality improves, and therefore rework is reduced. Process improvement often results in happier employees by reducing frustration.

When you have optimized a manual process, the next step is to explore process automation.

Be clear on what benefits you expect from automation

An automated process is better than a manual process, but automation is not free. Before you automate, it’s important to be clear on what benefits you expect from automation to ensure the effort to automate is cost-justified. This may be reduced labor, reduced wait states, reduced human error or a combo of the three. Let’s look at each in more detail.

Reduced labor

“From his neck down a man is worth a couple of dollars a day, from his neck up he is worth anything that his brain can produce.”

-Thomas Edison

Reduced labor results when mundane work that used to be done by a person is done by a computer. This is one of the most common reasons to automate a process. Free employees from the mechanics of labor and you may be surprised by what their brains produce.

Reduced wait states

Reducing or eliminating waiting in a process makes it more efficient. Besides, who likes to wait?

Reduced human error

To err is human. The more complex a process is, the more likely human errors will happen. When the complexity of a process can be clearly expressed in an algorithm and then written as code, the same set of inputs will always produce the same output.

Eliminating errors often has numerous downstream benefits, including less rework, better data, and happier employees and customers.

Know how much to automate

Once you have defined processes and know what you want out of automation, you need to ask yourself, “how much do I automate”? Start by examining an existing process. Determine the cost to perform each step manually. The cost to perform each step should be expressed in the terms of time spent doing, time spent waiting, and potential for human error. Each of these items can be extrapolated into a cost to the company.

Once this is done, you’ll be able to see where it makes sense to automate and where it doesn’t. Focus on automation that gives you the biggest bang for the buck. It is common to discover it makes sense to automate only a portion of a process.

Partial/Incremental automation

Partial or incremental automation does not completely automate a process. Instead, the goal is to have a computer do some portion of the process that a person is currently doing. Here’s an example.

Before

The tax department runs a massive data extract from the ETRM system into Excel, then creates a pivot table on the data to report taxes by state. Next, the amount of tax due to each state is determined and compared against the prior month. State filings are then done using each state’s website.

The data extract process is time-consuming for the tax team, creating a long wait state. And, because ETRM systems are not meant to be data extract systems, it’s also slowing down the system for other users.

After

An automated process gets the data from the ETRM’s database and puts it into Excel in the desired format. The tax team then uses the data in Excel to create their state filings. This process can either be initiated by a button click or scheduled to run when no users are in the system.

In this example only the data extract into Excel is automated. The remainder of the process to determine taxes due and generate the state filing is still manually performed by the tax team. However, automating the extract saves significant labor and wait time for the tax team.

Full process automation

As the name implies, full process automation completely removes a human from the process.

Here’s a great example. The receptionist at my dentist’s office used to call 1-2 days before my appointment to confirm I’d be there. I estimate calling every patient to confirm appoints took her 1-2 hours per day, especially with all the phone tag that was sure to happen.

She doesn’t call anymore. Now I get a text message with instructions to reply with “YES” if I will be there for my appointment. The whole process has been automated, resulting in reduced labor, reduced frustration for the customer and the receptionist, and no human error.

Choose a type of technology for automation

Different technologies can be used based on the automation problem you are trying to solve. Let’s look at some examples.

Micro-automation

There are some things almost too small to consider automating, but if you do anything often enough then the automation of that thing may be justifiable. For example, I type a lot. To save some keystrokes, I use a free program called AutoHotkey. It’s a script that monitors what I type and looks for certain keystroke combinations, which can be used to either perform actions or to replace something you typed with something else you were too efficient to type.

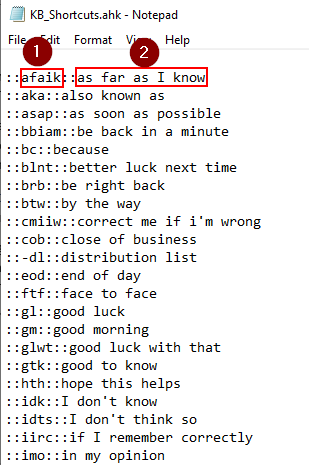

Here’s a screenshot of part of my script.

-

- This is what you type

- This is what appears in place of what you type.

I’m sure I save several hundred keystrokes per day by using this.

Report generation, data validation, data monitoring

Generating reports, validating data in reports, and checking for issues with data such as missing data, duplicate data, etc. are all things that can be automated. Having structured data as an input makes automating this process very simple.

This kind of work is among the most frequently automated.

Pro tip: Reporting on data that doesn’t meet expectations is very easy with exception reports, conditional formatting, etc. If you’re doing this stuff manually, you should investigate automating it. Right after you finish reading this blog post, of course.

Workflow automation

Many software applications have elements of workflow embedded in them. When I think of workflow, I think of applying a set of rules to work which routes the work accordingly.

For example, setting up a new counterparty to trade with requires a lot of up-front work. Workflow software makes tracking the state of the work much easier.

Robotic Process Automation (RPA)

Everyone’s talking about RPA these days, and it’s easy to see why. RPA technology enables a computer to do jobs that used to require a person. Examples include:

-

- Data entry

- Extracting data from websites

- Extracting data from PDFs, images, and other formats

- Testing the user interface of a software application

Here are some interesting ideas that are well within reach.

-

- Receive trade confirmation from a counterparty. Trader approves the confirmation. The RPA software creates the trade in the ETRM system.

- Generate trade confirmations from the ETRM system and send them to the counterparty.

- Extract data from natural gas pipeline EBBs and add the data to a database. (Schedulers, you’re welcome!)

- Compile a morning report for traders that shows weather, news, market prices and trends. Email it to the traders so it’s the first thing they see in the morning.

Do these ideas sound like fantasy? They’re not. At Veritas Total Solutions, we are using an RPA software called Blue Prism to help our clients accomplish these things, and much more.

The first 3 examples move existing work to an RPA bot. The fourth is an example of work that was just not feasible without RPA. It illustrates what you can do when you have unlimited free labor at your disposal. You’re only limited by your imagination!

RPA demand is rapidly increasing as more companies realize the opportunities that come with it. It’s the fastest growing type of automation because of the wide variety of problems it can solve.

Scale up and keep costs low

Whether you’re standardizing, improving, or automating your processes, there are always to improve upon your current processes and automation to increase cost savings and quality. Think about your current processes – do you have documented processes in place, do your processes exist but need refinement or are you ready to turn mundane tasks into automated processes? Wherever you are in your journey, we can help get you to the next step.

At Veritas Total Solutions, we can help you compile a complete process inventory per department, document those processes, select the best ones for automation and guide you through the automation implementation. Automation is quickly transitioning to RPA, which we are currently implementing for our clients. We have expertise in both Strategy and Transformation and Technology Solutions, making us uniquely qualified for process improvement and process automation in any industry. Contact us to get started.